Digital printing

Digital printing is the process we use in 90% of the notebooks we make. Color overlay and fidelity are perfectly achieved with this printing technology for short to medium runs.

We called digital printing to any kind of printing where the information is transferred directly to the printing press, in this process, the use of plates or press set-up is not required.

Digital printers produce high quality prints much faster than traditional printing and since prints come out dry, they can be manipulated immediately. Therefore, small runs can be print very quickly.

Screen Printing

Screen printing is a technique where ink is transferred through a mesh screen mounted on a frame. Ink is blocked off from the areas which are not to be printed by the use of an emulsion, leaving free areas where ink is pushed through.

The cost of screen printing depends on the number of colors used in the design, because each color requires a separate screen.

Screen printing is commonly used when white ink needs to be applied, because in digital printing white ink does not exist, white is consider the absence of ink on white paper. Although there are metallic inks for screen printing, hot stamping is the best option for metallic applications.

It is important to take into consideration that designs for screen printing need to be solid, it is not possible to achieve gradient effects.

At imakenotebooks, we use screen printing on kraft paper, printed laminated couche, matte papers and leather-like materials. It is not recommended to use it on fabric, because the weave itself deforms the shape of the design.

We use the Pantone Plus Solid Coated Guide to accurately chose color and for the correct preparation of the ink tone to be used.

This process is ideal for small or large runs because it is not expensive.

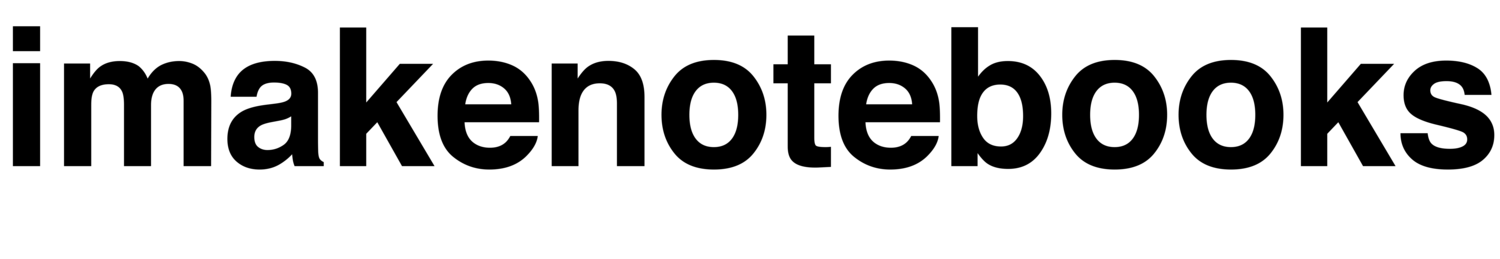

Hot Stamping

This is a dry printing method in which a foil is transferred to a surface using high temperature. It requires a die where the graphic element is engraved.

In Hot Stamping we cannot use Pantones or specific colors, only the foils made especially for this method.

This is the ideal method to stamp any metallic element.

For this process, particularly for notebooks covers, is important to consider that every graphic element requires a separate die and array and this has an impact on the cost.

The “array” is the position of the die against the cover to be stamped, so it fits the precise spot where we want the design to be. Once we have the correct array, we can stamp as many covers as needed.

For our notebooks we can apply hot stamping on kraft paper, printed and laminated couche, matte papers, fabric and leather-like materials.

This process is not recommended for small runs because it would be expensive.

Low relief debossing

Low relief debossing is a process similar to hot stamping: it requires a plate and a stamping machine; the process could either be cold or hot.

As in Hot Stamping, in this process, specifically for notebooks, each element requires a plate and an array. This is something that must be taken into consideration because of the effect on the cost.

An “array” is the position of the die against the cover to be stamped, so it fits the precise spot where the design has to be. Once we have the correct array, we can stamp as many covers as needed.

For our notebooks, low relief debossing can be applied on kraft paper, printed and laminated couche, matte papers, fabric and leather-like materials.

It works better on hard covers because the thickness of the cardboard makes the stamping more visible, on the contrary, on soft covers the stamping is very subtle.

This process is not recommended for small runs because it would expensive.

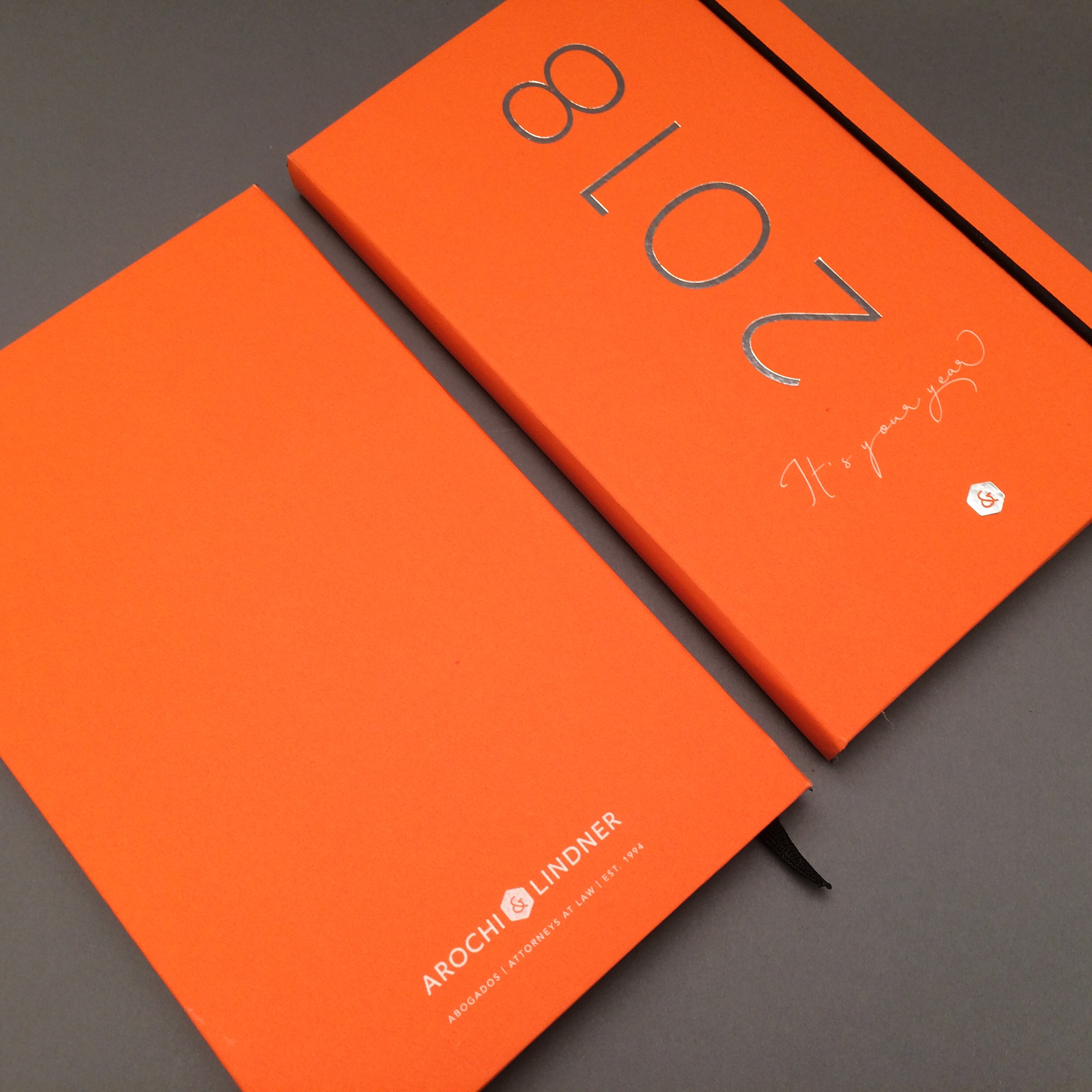

Digital foil and Spot varnish.

Digital foil is a process made in large printers. As in Hot Stamping it uses foils which come in different colors, but the foil is applied on the surface and there is no need to use pressure, the end product is visually similar to screen printing rather than Hot Stamping. The flatness of the printing is digitally controlled and it can be totally flat or a plaster that resembles dry liquid.

Digital foil is just like any other digital printing, but instead of printing data, foil is printed.

Unlike Hot Stamping it doesn’t require a plate, any element of the design can be printed digitally. But there are some considerations, the use of typographies less than 8 points are not recommended nor very thin lines.

For our notebooks, we use digital foil only on papers with matte laminate.

This method is ideal for spot varnish in which instead of using color foil a transparent foil is used to create a varnish look.

This process is recommended for medium runs, for small runs it is expensive.